What is an A3 Report or Analysis?

It's a 7 Step Proactive Problem-Solving Tool aimed at nullifying barriers and eliminating root causes. An A3 report utilises a single sheet of ISO A3-sized paper and provides a simple and strict procedure that guides problem-solving by workers.

There are two distinct categories of problem-solving:

Proactive (e.g. an A3 Report): activities are undertaken to address performance gaps identified by data analysis (e.g. key performance metrics)

Reactive (e.g. Global 8D): activities undertaken to respond to a specific customer complaint (e.g. product returns) where a corrective action response is requested, or "just do it" activities (e.g. equipment breakdown) or "quick kills" on a day-to-day basis.

In this blog, we're focusing on proactive problem-solving via the A3 Method.

Introduction, History, and Background

The concept of continuous improvement has developed so emphatically over the last few decades that it has now become a daily mantra for many, both professionally and personally.

"Problems" are commonplace in the workplace. These need to be systematically solved and actions need to be taken to avoid them reoccurring in the future. The implementation of A3 Problem Solving Thinking or the A3 Analysis Tool throughout your organisation eliminates problems once and for all.

Toyota has a reputation for operational excellence and performance through its lean and continuous improvement-based methods. Toyota developed and showed the world what can be achieved with its A3 Report method for solving problems effectively and efficiently. In late 1992 the Toyota Production System (TPS) was officially published as an initiative for continuous improvement. The A3 Report is one of the lean manufacturing tools and has played a major role in the success of Toyota. It is used worldwide in almost all industries, companies, and organizations.

A3 Reports, Problem-Solving, Thinking and Analysis

A3 problem solving is a structured approach utilising a single sheet of ISO A3-sized paper, hence its name.

It provides a simple and strict procedure that guides problem-solving by workers. It is similar to other problem-solving approaches that mirror Deming’s Plan-Do-Check-Act (PDCA) Cycle.

The Stakeholders of the A3 Problem-Solving Tool

The A3 Report won't help you solve problems in a matter of seconds - nothing can! The success of an A3 Report is found effective when Process Owners, Attendees, SMEs, and Implementors get involved in end-to-end closures.

5 major stakeholders play an important role in the success and execution of an A3 Report:

Leader maintains all relevant documents about the A3 Report and leads the team

The CFT/Multi-Disciplinary Team are the Process Owners or the Team of Subject Matter Expertise (SMEs)

SCRUM Mentor/Coach fills the gaps in the execution of the A3 Report by constantly guiding and coaching the team. S/he is a master in the subject and provokes, guides & motivates the CFT to find solutions across the tasks and causes identified

Implementors are the stakeholders who implement and execute the tasks assigned by the CFT. Without these stakeholders' involvement, the implementation becomes almost impossible

Management is those who back the A3 Report Team with capital investments and are keen on results. Management shall always be available to support the A3 Project Team.

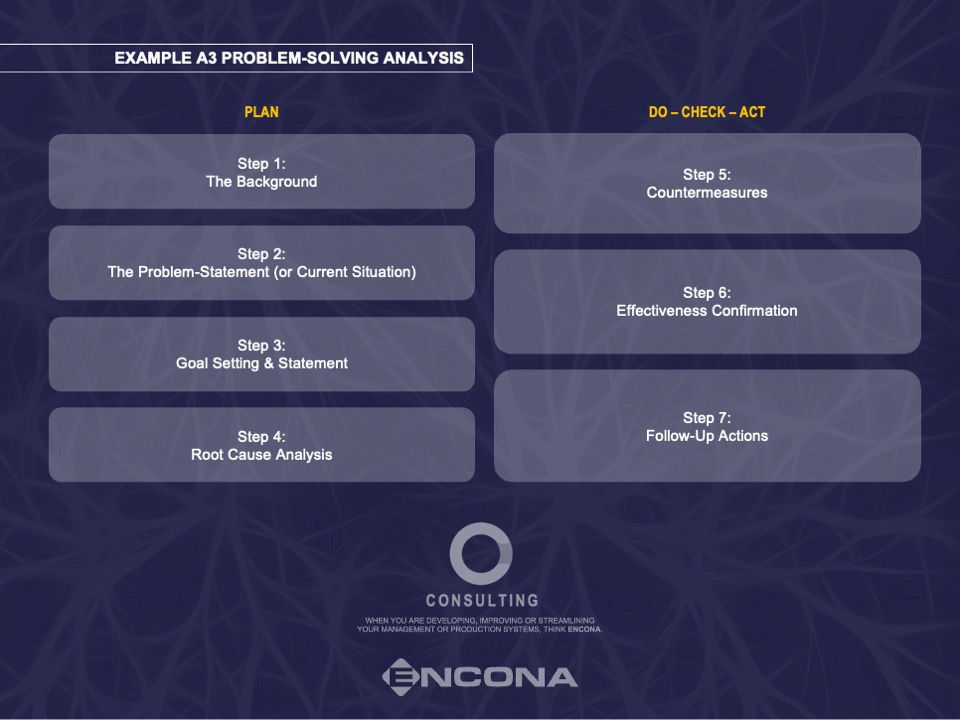

The 7 Steps* of an A3 Report

* also known as Pillars or Phases

The A3 Single Page Report typically comprises 7 steps that reflect the entire process execution. However, you may wish to add steps specific to your use case to achieve more effective results.

Step 1: The Background

This is where an organisation identifies and selects the problem for resolution. First, explore why change is required and the link to the business strategy. Then, identify the worst and most affected problems by Pareto Analysis or the 0:20 Rule or Diagram.

Once you have selected the problem for resolution, clearly and briefly define the aspects that affect the problem and impact the goals, targets, strategic business planning around customers, processes, financials, new products, etc. Ensure that a clear study and background analysis have been made in all the areas where the problem has arisen over some time.

Step 2: The Problem Statement (or Current Situation)

This is the step where you need to define the current situation of the problem. Ensure that Where, When, Who, How, and What are clearly defined & addressed.

The problem can be qualitative as well as quantitative in nature. Ensure that the impact of the problem in the organisation, given the current situation, will be addressed effectively at the root. Use data, charts, graphs, maps in this step to represent the current situation as accurately as possible.

Step 3: Goal Setting & Statement

In this step, you clarify what you are going to achieve, i.e. the desired result(s). Goals with clear, measurable targets should be defined. Avoid goals that cannot be measured. The goals can be either phase-wise based or on a project timeline basis, such as weekly or monthly and should relate to your problem statement. Use a SMART (Specific, Measurable, Achievable, Relevant, and Time-bound ) target.

Step 4: Root Cause Analysis

This is potentially the most important step in all A3 report examples. Quick fixes often mask the real root cause. Unresolved, the problem resurfaces, hindering long-term success. There are several effective tools that can be used to find the root cause of a problem. Two such tools are the 5-Why Analysis or the Why-Why Analysis, which use Cause and Effect/Fish Bone Diagrams and IS/IS Not Check sheets.

Step 5: Countermeasures

Clarify the corrective actions to be taken and provide solutions based on the root cause identified in Step 4. Always focus on solutions that will eliminate the identified root cause(s). Assign the tasks to the implementors for the implementation of corrective actions.

You can also go back to Step 2 and set a few more goals that may have been established from your solutions. Design and draw a detailed plan for the successful implementation of corrective actions.

Step 6: Effectiveness Confirmation

The effectiveness of the A3 Project or A3 Process Implementation is measured against the set targets. Examples should be set which will help in the future solving of new problems that arise. A benchmark should be maintained to assist other stakeholders who get involved in future A3 Projects. Evaluate effectiveness through various methods, including feedback surveys, focused audits, key performance indicator (KPI) tracking, and on-site Gemba studies.

Step 7: Follow-up Actions

Once the efficacy is monitored, ensure the sustainability of the actions implemented via standardisation, audits, reviews, and daily target tracking via dashboard management. Implement corrective actions based on the results of the deviations against targets, revisit the A3 Report, modify the plan, and re-implement the actions. For positive results, circulate the results and methods across the organisation in the form of standardisation.

Why Implement an A3 Report?

In all examples of A3 report implementation, it drives the continuous improvement culture. The tool has a great impact and makes communication simple. It allows lean management in the automotive industry through minimal use of resources and is an effective tool for mid-level managers and supervisors. The A3 Report is very effective in solving problems when JIT solutions are required.

CONCLUSION:

Benefits of the A3 Problem-Solving Model

This 1-page report effectively solves problems due to it:

being clear and precise

involving all stakeholders in a collaborative manner

focused on continuous improvement across the organization

promoting cross-organizational sharing between various groups and stakeholders

being focused, committed to goals, and target-driven

being an effective tool for coaching others and a platform for learning, a benefit of the involvement of a coach, a facilitator, or a SCRUM master

being a promoter of the lean management concept across the organization, focusing on waste minimization through the use of minimal resources.

Need expert problem-solving in your manufacturing organization? Discover our consulting services or contact us on enquiries@encona.org

Comments